Category

Torsion Bar Synchronous Nc Press Brake Machine Kcn-8032

Torsion bar Synchronous NC Press Brake Model: KCN-8032 2 Axis CNC Control(X, Y,) X: Backgauge front and back; Y: Ram str

Basic Info

| Model NO. | KCN-8032 |

| Warranty | 2-year |

| Condition | New |

| Certification | CE |

| Automation | Automatic |

| Suitable for | Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel |

| Type | Press Brake |

| Table Length | 3200mm |

| Max.Slider Stroke | 120mm |

| Between Columns | 2600mm |

| Throat Depth | 320mm |

| Main Motor Power | 7.5kw |

| Voltage | 220/380/Customized |

| Controller System | E21s |

| Return Speed | 90mm/S |

| Gear Pump | Sunny |

| Brand | Kingball |

| Backgauge Stoppers | 2 |

| Transport Package | Plastic |

| Specification | 3700*1600*2300mm |

| Trademark | KINGBALL |

| Origin | China |

| HS Code | 84622990 |

| Production Capacity | 200/Sets/Month |

Product Description

Torsion bar Synchronous NC Press BrakeModel: KCN-8032

2 Axis CNC Control(X, Y,)

X: Backgauge front and back; Y: Ram stroke

W: Worktable crowning (optional)

Main functions and features

Overall welded and processed structure.

High mechanical strength and strong rigidity.

Ram stroke hydraulic approaching downward, stable and reliable.

E21 can control the movement of ram stroke and backgauge, achieving efficient and highly precise positioning.

Wedge compensation on top punch clamping.

Simplified top blades clamping with micro-adjustment wedges,for easy operation and high precision.

2 Sliding front sheet support arms mounted onto T slot of the bed.

Solid one block four face multi V die.

Approved stable and reliable hydraulics.

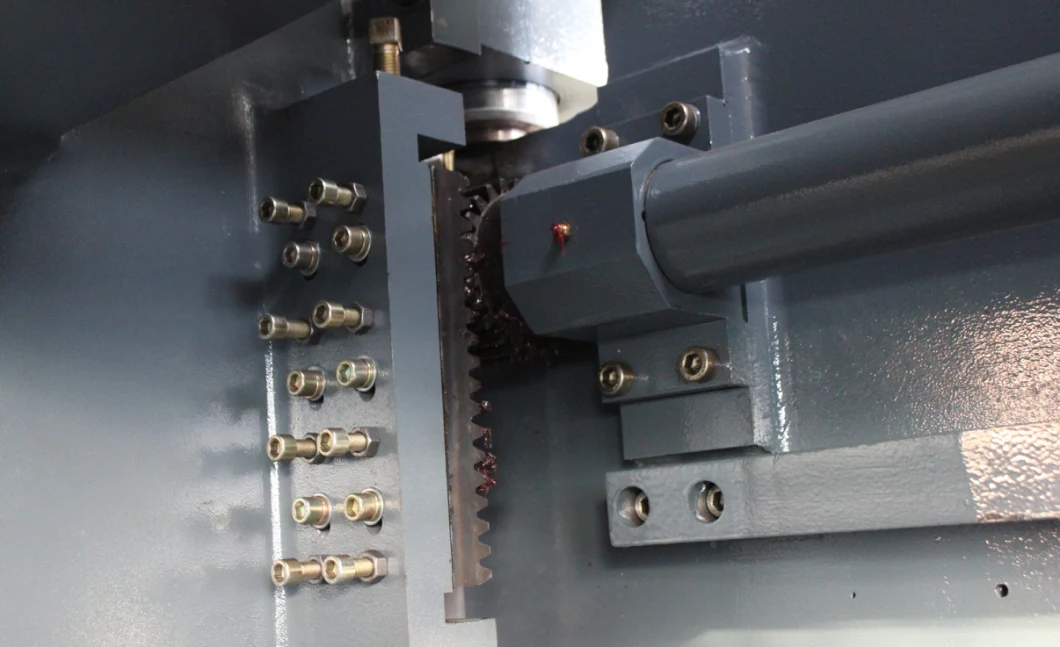

Stop fingers with milscale for plate bending machine.

Technical Parameters

| No. | Item | Parameter | Unit |

| 1 | Nominal pressure | 800 | KN |

| 2 | Table length | 3200 | mm |

| 3 | Max.Slider stroke | 120 | mm |

| 4 | Max.Shut height | 380 | mm |

| 5 | Between columns | 2600 | mm |

| 6 | Throat depth | 320 | mm |

| 7 | Main motor power | 7.5 | KW |

| 8 | Down Speed | 100 | mm/S |

| 9 | Pressing Speed | 10 | mm/S |

| 10 | Return Speed | 90 | mm/S |

| 11 | Control axes | X+Y | / |

| 12 | X axes Stroke | 500 | mm |

| 13 | Backgauge Stoppers | 2 | / |

| 14 | Overall dimension | L 3700 | mm |

| W 1600 | mm | ||

| H 2300 | mm | ||

| 15 | Weight | 5500 | kg |

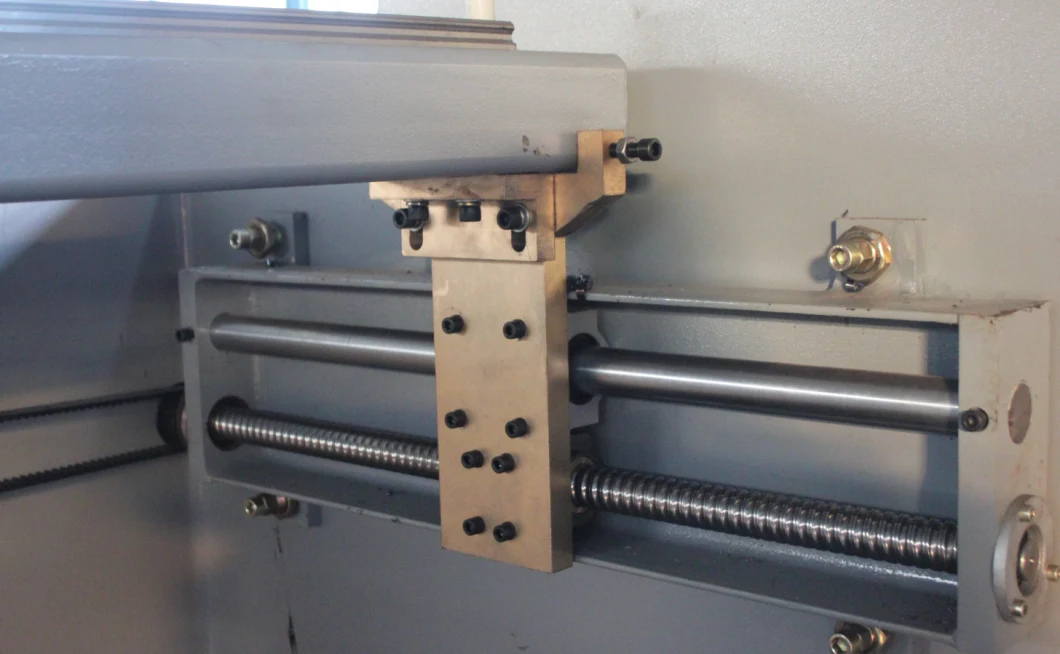

Backgauge with ball screw and round guide

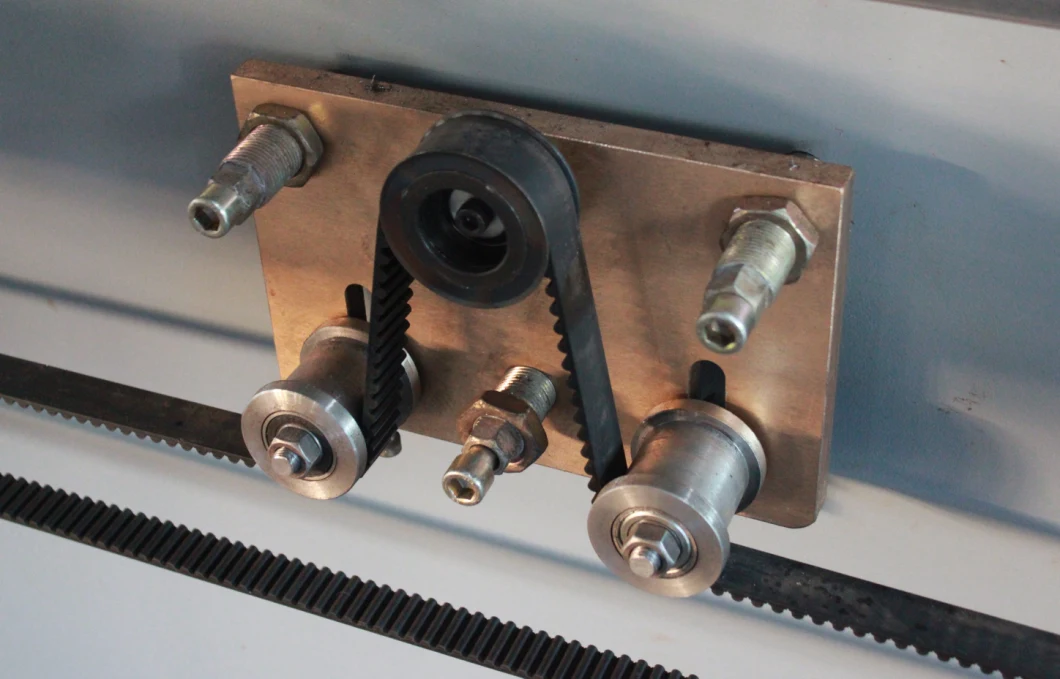

Multifunction adjustment of the tightening wheel. Manual table crowning(optional).

Siemens main motor German brand.

European style quick release clamping

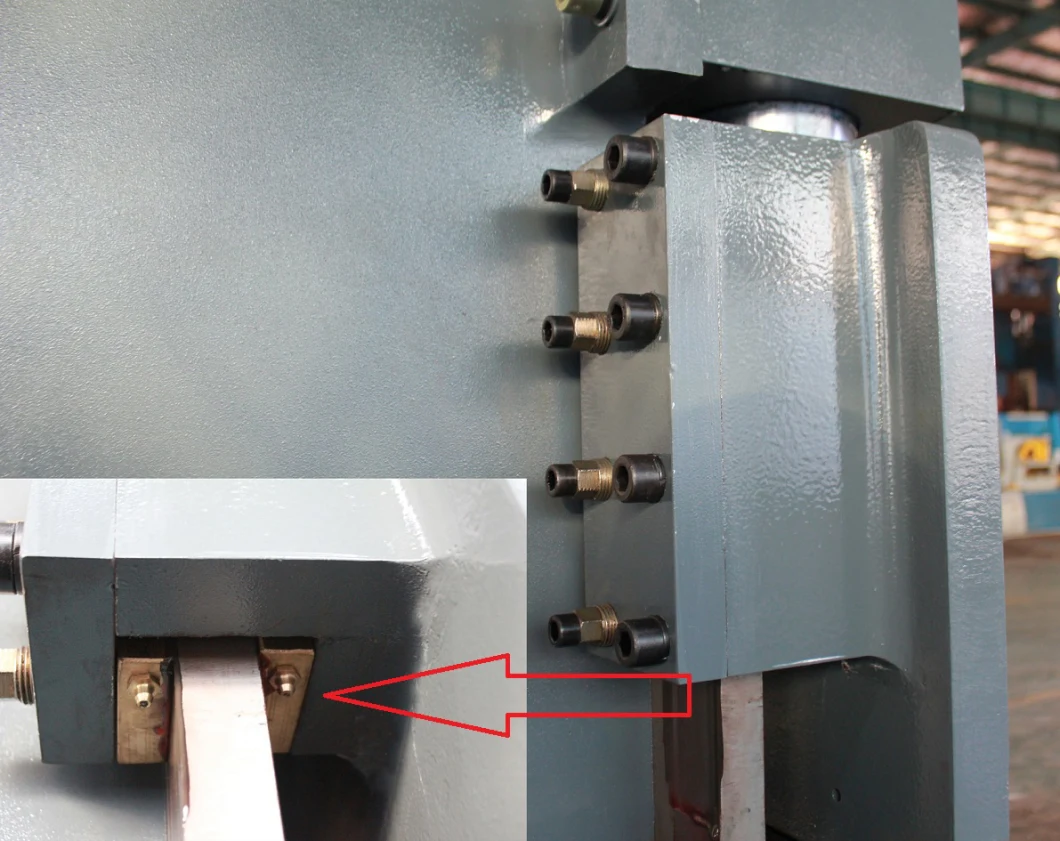

The guideway use the brass, wear-resisting, long service life.Pedal switch with emergency stop, safe operation, the base with rollers easy to move.

The torsion bar is synchronized with the gear rack. ram down fast, easy to adjust the two sides of the synchronization.The connector use wear - resistant brass.

The stopper up and down by manual, move left and right on two linear guides.

Main configuration

| Name | Producer |

| CNC controller | E21 Estun China Brand |

| Main motor | Siemens Germany brand |

| Electrical components | Schneider France brand |

| Gear pump | Sunny USA brand |

| Seal ring | NOK Japan brand |

| Hydraulic system | Boschrexroth Germany brand |

| Ball screw ,Linear guide | HIWIN Taiwan brand |

| Tubing connector | EMB Germany Brand |

| Variable frequency drive | Shihlin Taiwan brand |

Backgauge and block control

Control for general AC motors, frequency inverter Intelligent positioning

Stock counter Holding/decompression time setting

Program memory of up to 40 programs Up to 25 steps per program

One side positioning Retract function

One key backup/restore of parameters mm/inch

Chinese /English

The standard accessories are in the below:

- Anchor bolt

- Hex nut

- Seal ring

- Gasket

- Grease gun

- Allen wrench

- Foot switch

- Front support arms

- Electrical box key, control panel key

- Operation manuals

Press brake is packaged by plastic,toolings are packaged by wooden.

Our Service

Pre-sales services:

1. inquiry and consulting support

2. sample testing support

3. visit our factory

After-sales services:

1. 2 years warranty period

2. training how to install and use the brake press machine

3. engineers available to service machinery overseas